If you’ve ever opened a water tank inspection companies report and thought, “Well… that escalated quickly,” you’re not alone.

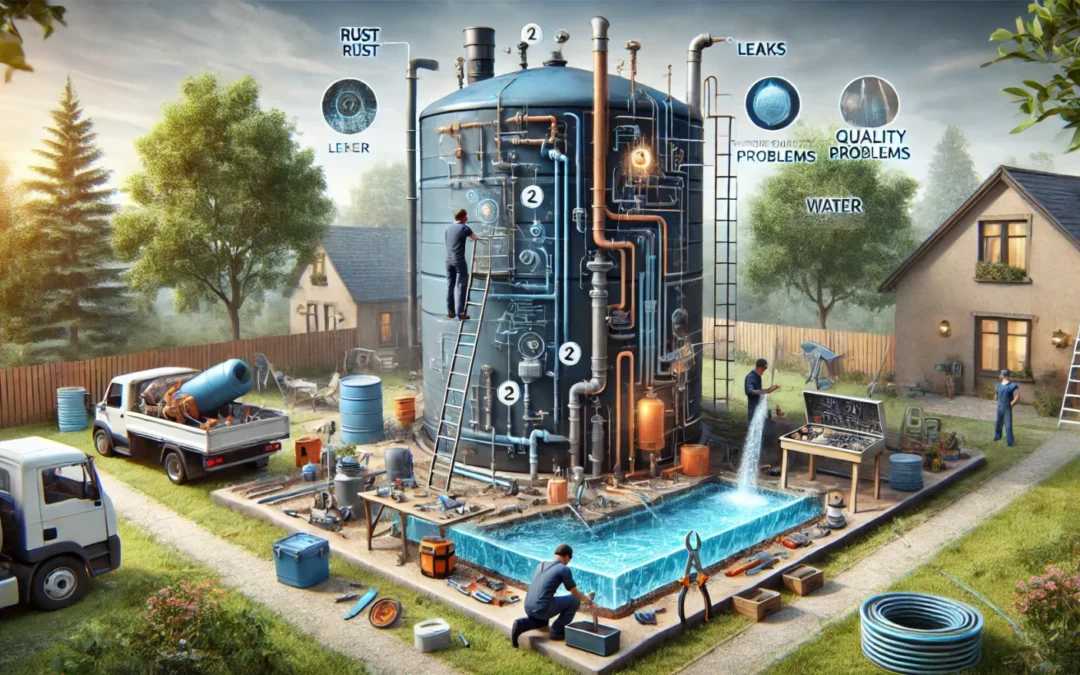

From the outside, most water tanks look fine. Solid. Quiet. Just sitting there doing their job. But inspectors know better. Once you get inside—or under, or around—the story usually changes. Corrosion here, a mystery leak there, something slightly off that doesn’t feel urgent… until it is.

Let’s talk about the most common water tank defects inspection services run into, and more importantly, what actually fixes them. Not theory. Real-world stuff.

1. Internal Corrosion

This one tops the list every time.

Internal corrosion usually shows up on tank floors, lower shell courses, weld seams, and around nozzles. It’s sneaky because potable water feels harmless. But oxygen, minerals, disinfectants, and coating breakdown all work together over time.

Inspectors often find:

- Localized pitting

- General wall thinning

- Coating delamination

How to fix it:

First, assess the extent. Spot corrosion might just need surface prep and recoating. Widespread thinning? That’s when repair plates, floor replacement, or section repairs come into play.

Also—this matters—fixing corrosion without fixing the coating system or water chemistry is basically pressing pause, not solve.

2. External Corrosion

This one frustrates facility owners the most.

From ground level, the tank looks fine. Up close, inspectors at water storage tank inspection companies find corrosion under insulation, at roof-to-shell junctions, around stair attachments, or right where rainwater likes to sit.

External corrosion thrives where:

- Paint systems fail

- Water gets trapped

- Dissimilar metals meet

How to fix it:

Surface prep, coating repairs, and sometimes structural steel replacement. But the long-term fix is better drainage, proper detailing, and realistic coating maintenance cycles.

Ignoring external corrosion because it’s “not leaking yet” is how small problems turn into expensive ones.

3. Roof and Vent Issues

Tank roofs don’t get much attention until something goes wrong. Inspectors regularly find:

- Corroded roof plates

- Cracked welds

- Blocked or damaged vents

Blocked vents are especially dangerous—they can lead to pressure issues and roof deformation.

How to fix it:

Repair or replace damaged roof sections, clean and repair vents, and verify vent sizing meets current standards. It’s boring work, honestly—but critical.

4. Leaks That Aren’t Obvious

Not all leaks announce themselves with puddles.

Some show up as:

- Unexplained water loss

- Damp soil near the foundation

- Corrosion streaks on the shell

Inspectors often trace these back to floor corrosion, nozzle welds, or roof penetrations.

How to fix it:

Leak location comes first. Then targeted repairs—weld repairs, floor patches, nozzle reinforcement. Temporary fixes can buy time, but permanent repairs are the goal.

And yes, draining the tank is often unavoidable. Nobody loves that part.

5. Foundation and Settlement Problems

This is where things get serious.

Settlement shows up as:

- Uneven floors

- Shell distortion

- Out-of-round conditions

Inspectors catch this using elevation surveys and visual distortion checks.

How to fix it:

Minor settlement might be monitored. Active or uneven settlement usually needs foundation repair, soil stabilization, or re-leveling. Structural engineers get involved here—and for good reason.

Ignoring settlement is how tanks quietly fail.

6. Failed or Aging Coating Systems

Coatings don’t last forever, no matter what the brochure promised.

Inspectors commonly see:

- Blistering

- Peeling

- Underfilm corrosion

Once coatings fail, corrosion accelerates fast.

How to fix it:

Full or partial recoating after proper surface prep. Shortcutting prep is the fastest way to waste money on coatings.

Why Inspections Matter More Than Ever

Most of these defects don’t happen overnight. They develop slowly, quietly, and politely—until they don’t.

Regular api 653 tank inspection services aren’t about finding problems. They’re about finding them early, when fixes are still manageable and budgets aren’t blown apart.

Final Thought

Water tanks are easy to forget about because they usually behave. But when they fail, the consequences are messy, expensive, and public.

Inspection services don’t just point out what’s wrong—they give you a chance to fix things while you still have options. And that’s worth a lot more than a clean-looking exterior.

FAQs

1. How often should water tanks be inspected?

Typically every 3–5 years internally, with regular external inspections in between. Regulations may vary.

2. Is corrosion inevitable?

Eventually, yes. But good coatings, maintenance, and inspections slow it way down.

3. Can small leaks be monitored instead of repaired?

Short-term, maybe. Long-term, that’s a risky gamble.

4. Are inspections disruptive to operations?

Internal inspections usually require draining. Planning ahead makes a big difference.

5. What’s the most commonly missed defect?

External corrosion in hard-to-see areas—hands down.