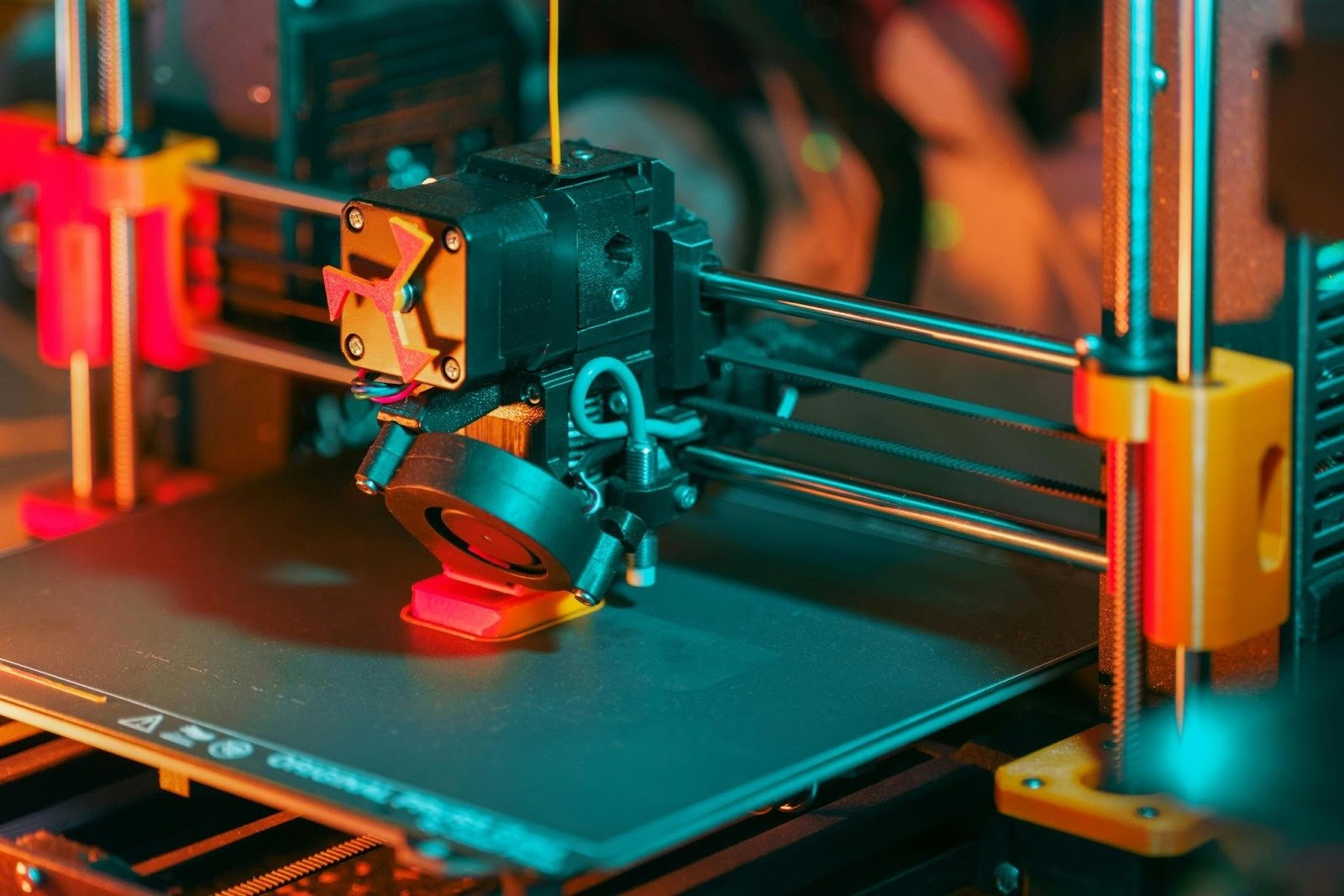

Custom tooling delays are budget killers. You know the drill: design revisions roll in—they always do—and suddenly you’re stuck waiting weeks for machined fixtures while production sits frozen. Here’s the thing, though. Manufacturers deploying 3D printing in manufacturing are sidestepping this mess entirely.

They’re rolling out 3D printing tooling and 3D printed fixtures that validate in days, swap configurations on the fly, and plug straight into smart manufacturing solutions tracking every version.But here’s what most teams miss: launching a tooling initiative without defining success metrics is like driving blindfolded. “Faster and cheaper” won’t cut it when you need to justify spending or make trade-off calls.

Tooling and Fixture Performance Metrics That Matter on the Shop Floor

If you’re serious about additive manufacturing for tooling, start tracking numbers immediately. Lead time cuts matter most during iteration cycles—how fast do you move from a CAD tweak to a validated fixture actually running? First-pass yield tells you if better fixtures are cutting operator mistakes and scrap. And downtime? That’s pure OEE impact.

Here’s reality: traditional CNC-milled molds take weeks and months to nail down the final design.. Compound that when production shifts demand fresh tooling versions.

Critical KPIs for 3D Printing Tooling Programs

Design-to-deploy time is your north star. Prototype fixtures? Shoot for 24–72 hours. Production stuff needs validation, so 5–7 days is reasonable. Count how many design loops happen before release—that’s where 3D printing tooling embarrasses outsourced machining. Softer wins like ergonomics and scrap drops show up in operator surveys and quality dashboards. Many teams lean on experienced 3d printing Services to validate initial fixture batches and lock down reliable baselines for material picks, tolerances, and repeatable outcomes before scaling in-house.

Tolerance and Repeatability Expectations by Process

FDM lands at ± 0.2 — 0.5 mm raw, tighter if you ream critical datums. SLA and DLP? ±0.1 mm for inspection gear. SLS and MJF deliver ±0.3 mm with isotropic strength—critical when clamp forces matter. Calibration, shrink comp, and datum planning bridge the gap from “as-printed” to “production-worthy.”

Once KPIs are locked, you’ll spot where 3D printed fixtures deliver the fastest, clearest wins.

3D Printed Fixtures and Jigs That Deliver Immediate Wins

Assembly fixtures are your quickest payoff. Poka-yoke geometry and keyed locators stop mistakes cold. Integrated labels and asymmetric features accelerate training. Inspection fixtures—CMM nests, handheld measurement tools, go/no-go gauges—slash setup because conformal surfaces match part geometry better than generic steel ever could.

Assembly Fixtures Optimized for Speed and Error-Proofing

Build mistake-proofing directly into fixtures. If parts only fit one way, operators can’t mess it up. Embed color codes or labels during the print—no confusion on mixed-model lines. Asymmetric locators block backward installation. Modular nests let you swap configs without retooling baseplates.

Inspection Fixtures and Metrology Aids

Tough resin or PA12 check gauges validate dimensions faster than queuing for CMM time. Handheld guides let operators measure critical features solo. Go/no-go gauges with conformal surfaces match part contours exactly, killing interpretation errors. These tools pay for themselves in days once inspection bottlenecks clear.

Knowing *what* to print matters. But picking the *right* process ensures fixtures hit performance, tolerance, and durability targets without burning budget.

Additive Manufacturing for Tooling Across Processes

FDM gives you functional tooling at rock-bottom per-fixture costs. Strength runs along the print direction, so orient for load paths. Infill strategy counts: 40–60% gyroid or cubic handles most clamp forces, while perimeters add impact resistance. Carbon fiber or glass fills boost stiffness when thin walls face deflection.

FDM for Functional Tooling at the Lowest Cost per Fixture

Best fits? Assembly jigs, drill templates, soft-grip end effectors. PETG handles general fixtures; ABS/ASA takes heat and impact; Nylon adds toughness for repeated clamp cycles. Continuous fiber inserts transform printed bodies into serious load-bearing tools. Catch: cross-layer cleavage is real if orientation gets ignored.

SLS/MJF for Durable, Production-Ready 3D Printed Fixtures

PA12 baseline powder delivers isotropic strength—fixtures perform uniformly regardless of build orientation. No supports unlock wild geometries: internal channels, integrated hinges, nested assemblies. Batch nesting cranks throughput—pack the build chamber and let it run overnight. Surface finishing like vapor smoothing or dyeing adds polish when customer-facing quality matters. Even brilliant printing tech fails when material can’t survive factory reality. Matching polymer properties to operational stress is non-negotiable.

Material Selection Playbook for Smarter Tooling and Fixture Strategies

Heat, chemicals, abrasion, creep, impact—factory floors throw everything at fixtures. Map environment to material properties before you commit. PLA? Fit-check only. PETG handles general fixtures exposed to oils. ABS/ASA withstand moderate temps and impact. Nylon delivers toughness for repeated use; PC resists higher heat. High-performance PEI or PEEK tackle extremes but cost more and demand heated chambers.

FDM Materials for 3D Printing Tooling

Quick rules: PETG for assembly jigs. ABS/ASA when impact or temp spikes hit. Nylon when toughness beats stiffness. PC for sustained heat. Carbon or glass fills add rigidity without weight penalty. ESD-safe variants protect electronics assembly. Match material to use case, not hype—overspecifying wastes money without performance gains.

Adhesives, Coatings, and Liners That Extend Fixture Life

Low-friction PTFE tape on wear zones triples lifespan. Epoxy sealing closes porosity on SLS parts exposed to cutting fluids. Conformal coatings block chemicals. TPU liners on grippers prevent scratching Class-A surfaces. Sacrificial skins on high-abrasion contact points let you replace cheap layers instead of reprinting entire fixtures.

Material choice sets the foundation. But unlocking full fixture potential demands design strategies conventional machining would never allow.

Design Strategies That Make 3D Printed Fixtures Production-Ready

Datum-first design ensures repeatability. Define A/B/C datums early, control contact points, apply kinematic location principles so fixtures self-align. Modular datum features let you adjust when tolerances stack unexpectedly. Strength comes from ribbing, gussets, and lattice strategies—not thick walls that waste material and print time. Orientation matters: align load paths with layer direction in FDM.

Commercial software using ML and DL hit 98.8% success rates in automated solutions, proving AI-enabled workflows validate designs reliably before printing.

Datum-First Design for Repeatability and Quick Inspection

Every fixture starts with defined datum surfaces. Controlled contact points—three for A, two for B, one for C—establish consistent part location. Kinematic principles mean fixtures self-clock without fighting tolerances. Modular datum inserts let you tweak location when production parts drift from nominal, dodging full reprints when small adjustments solve fit issues.

Built-In Adjustability for Real-World Variation

Slotted locators absorb stack-up. Shim pockets let you fine-tune height or angle on the floor. Eccentric cams provide micro-adjustment without tools. Compliant features—thin living hinges or flexible tabs—accommodate part variation gracefully. Design for messy reality, not perfect CAD, and fixtures work first time more often.

Smart fixture design only goes so far without digital infrastructure managing, updating, and deploying it—smart manufacturing solutions create lasting competitive edge here.

Launch Smarter Tooling With Expert Support

You’ve got frameworks, KPIs, and troubleshooting strategies. Now execute. Evaluate candidate fixtures—which three deliver fastest ROI? Match materials to your environment: heat, chemicals, abrasion. Choose a printer and process based on tolerance needs, not marketing hype. A structured “Tooling & Fixture Readiness Review” shortlists candidates, estimates ROI, recommends materials and processes so you skip trial-and-error.

Common Questions About 3D Printed Tooling

Can 3D printed fixtures handle production environments, not just prototyping?

Absolutely, when material and design match application. PA12 SLS fixtures run thousands of cycles. Carbon-filled FDM supports moderate clamping forces. Validation testing confirms durability before line deployment.

Which 3D printing process works best for fixtures: FDM, SLA, or SLS/MJF?

FDM wins on cost for larger fixtures. SLA delivers tight tolerances for inspection aids. SLS/MJF offers isotropic strength and batch efficiency for durable production tooling without support.

How accurate are 3D printed fixtures for GD&T and tight-tolerance applications?

SLA hits ±0.1 mm; FDM achieves ±0.2–0.5 mm; SLS lands around ±0.3 mm. Post-processing—reaming, boring, or datum machining—tightens critical interfaces to meet GD&T callouts reliably.

Final Thoughts on Smarter Tooling Strategies

3D printing tooling and 3D printed fixtures aren’t future-tech anymore. They’re practical tools slashing lead times, demolishing costs, and enabling iteration speeds traditional machining can’t touch.

Winning shops treat tooling as digital assets, not physical inventory burdens. Start with high-impact candidates, validate performance with clear KPIs, and build workflow infrastructure that scales across plants. Speed matters, sure. But repeatability and control matter more. Nail those, and you’ll wonder how you ever tolerated weeks-long tooling delays.